The innovative PIF

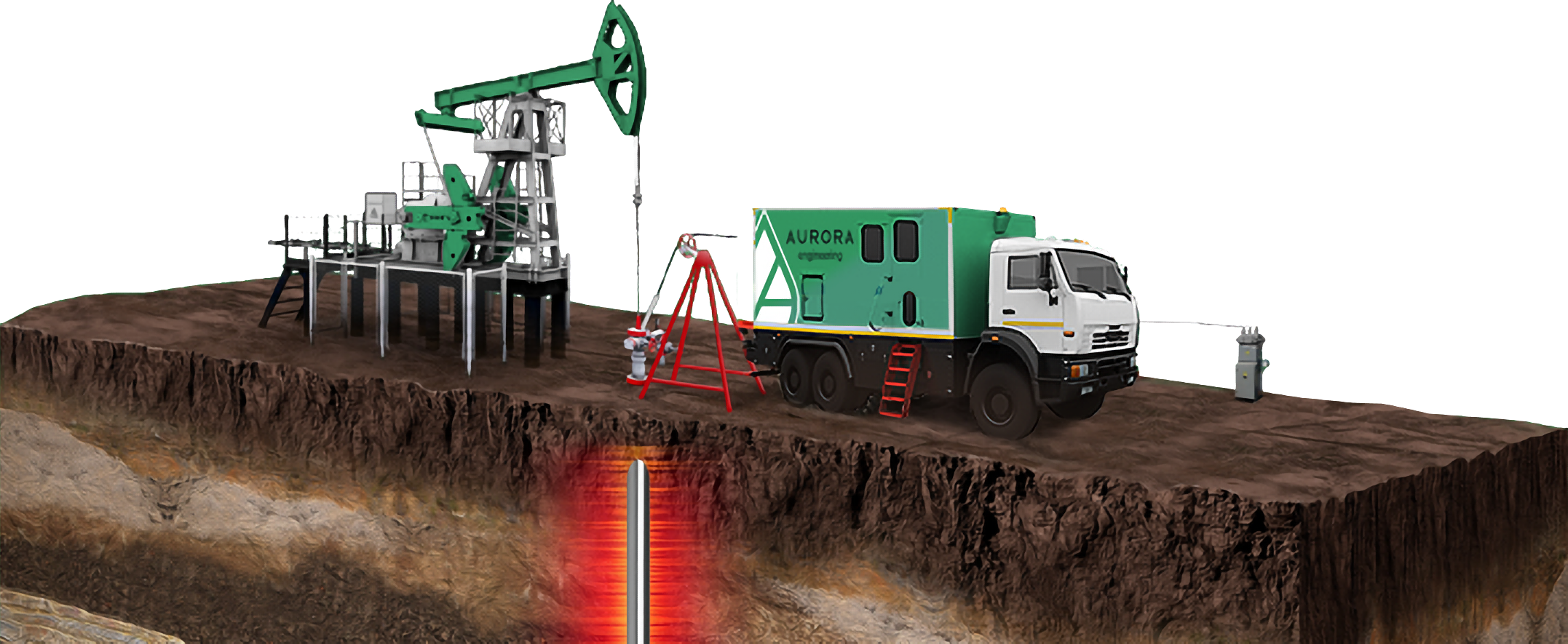

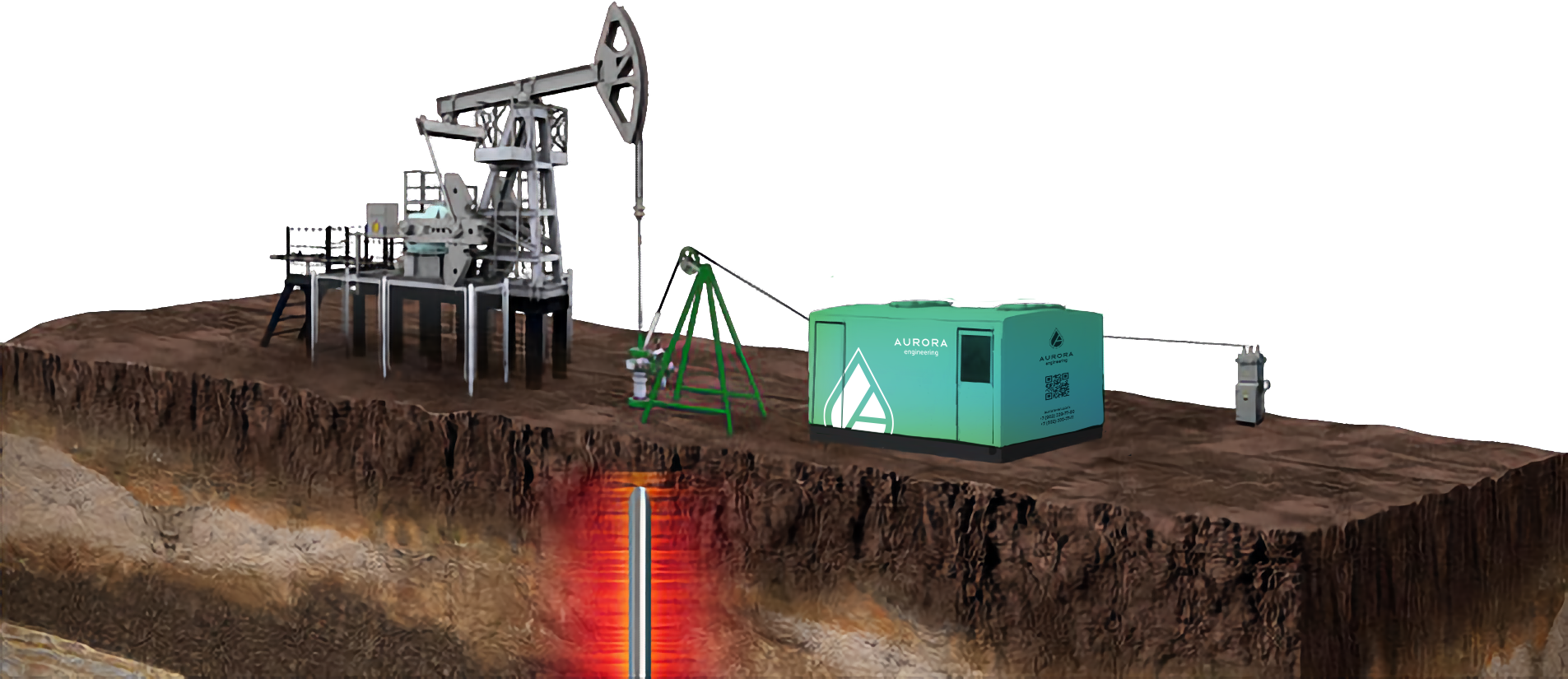

technology makes it possible to multiply the volume of oil producedPIF technology is used for maintenance work on oil-producing wells.

It is used in the extraction of hard-to-recover oil reserves, the prevention and elimination of asphalt-resin-paraffin deposits and the deposition of emulsions, hydrates, as well as in the transshipment of viscous products: fuel oil, bitumen, oil, oil sludge.

- equalization of temperature along the length of reducing losses in the initial section;

- reduction of losses due to lower pumping temperature;

- reduction of energy consumption by pumps by reducing surface friction.

The compatibility of the equipment with the cable and the synchronicity of their operation in the common cable network from the switching power supply with subsequent power generation

Independent power supply of the network from one or more devices connected to the feeder line throughout the field – from the bottom of the well, on the discharge lines and collectors and to the point of separation and oil treatment

Due to the principle of equipment compatibility, the technology is not limited by the length or volume of objects — this makes it possible to use PIF on long and ultra-long main pipelines.

445075, Samara region, Samara, Evgeniya Zolotukhina street, 4-120

All rights reserved